ボイスコイルアクチュエータ

- Linear Voice Coil Actuators

- Maximum Travel Ranges from 6.4 mm to 63.5 mm

- High Purity of Motion

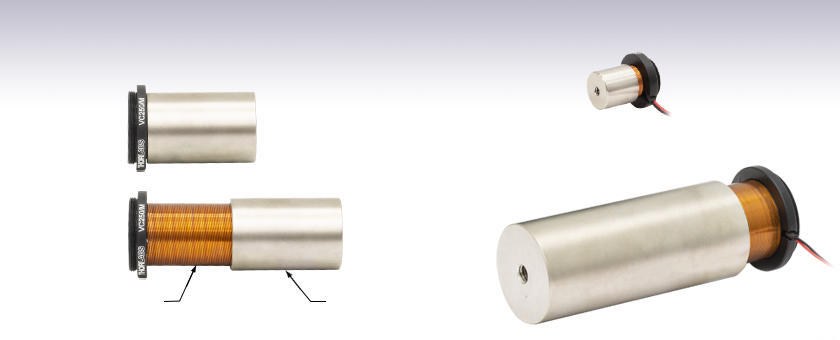

VC250/M

Voice Coil Actuator,

25.4 mm Travel

Zero Travel Position

Maximum Travel

VC063

Voice Coil Actuator,

1/4" Travel

VC625

Voice Coil Actuator,

2.5" Travel

Coil Assembly

Magnet Assembly

Please Wait

Click to Enlarge

コイルアセンブリの上部には、他の部品を取り付けるためのSMネジとネジ穴が付いています。詳しくは下表をご参照ください。

特長

- リニアボイスコイルモータ

- ダイレクトドライブ方式

- 最大移動量63.5 mm

- 電流駆動方式

- 高速、精密移動

- 応答性の高い加速・減速

- SMネジ付きコイルアセンブリ

ボイスコイルアクチュエータは、高速あるいは高加速度での位置決めを必要とする用途向けに設計されています。これらのリニアアクチュエータはコイルアセンブリと磁石アセンブリから構成され、可動部と固定部の間に直線的に動く力を非接触で供給します。ボイスコイルは電気信号を磁場を介して直線的に動くための力に変換するため、優れた動作特性を実現できます。これは、ベルトやギアなどのドライブトレーンを別途必要とするDCモータと比較して大きく異なる点です。ボイスコイルに位置センサを組み合わせると、高速で正確、かつ再現性にも優れた運動を実現できます。モータの動作方向は電圧の極性で決まります。赤のワイヤを正電圧に接続して電流を流すと、磁石アセンブリはアクチュエータが伸長する方向に移動します。発生する力は、アクチュエータの位置にも依存しますが、電流に力定数(Force Constant)を乗じることで概算できます(詳細は下表のグラフをクリックしてご覧ください)。

すべてのボイスコイルアセンブリにはSM外ネジが付いており、当社の固定式光学マウントやレンズチューブに取り付けることができます。磁石アセンブリがコイルに接触することなく浮遊するように、ボイスコイルアクチュエータの両端をしっかり取り付ける必要があります。ミリ規格のSM05外ネジ付きのコイル、VC063B/M、およびVC125B/Mの中央にはM3取付け穴があり、それらの磁石アセンブリの中央にはM3取付け穴(止り穴)があります。コイルVC380/Mの中央にはM3取付け穴があり、その磁石アセンブリの中央にはM6取付け穴(止り穴)があります。ミリ規格のSM1およびSM2ネジ付きボイスコイルの磁石アセンブリ中央にはM6取付け穴(止り穴)があり、それらのコイルアセンブリには中央のØ6.4 mm貫通穴を挟んで2つのM4取付け穴があります。これらの取付け穴と当社の直角ブラケットを使用すれば、ボイスコイルのどちらかの端を光学テーブルやステージの可動部に固定することができます。

ボイスコイルアクチュエータを推奨する最大移動範囲を超えて移動させると、磁石アセンブリの位置がコイルアセンブリから遠くなりすぎて適切な磁気的相互作用が維持できなくなります。そうなった場合は、アクチュエータは期待するようには動作しなくなるので、ボイスコイルを手動で縮める必要があります。

ステンレススチール製筐体の中央にあるタップ穴に鉄製のものなどを取付けないでください。永久磁石の位置がずれて、アセンブリの修理が必要になる場合があります。ボイスコイルアクチュエータのネジ穴の最大深さは、下表のInfoアイコンをクリックして「Mounting Features」欄を開くとご覧いただけます。磁石が外れてしまった場合は、当社までご連絡ください。

ボイスコイルアクチュエータの動作仕様

当社のボイスコイルアクチュエータは、定電流/電圧可変または定電圧/電流可変のどちらかで動作させます。下の表では、コイルの動作温度とデューティサイクルが与えられたときの電気的な動作仕様をご覧いただけます。定電流での動作仕様は、IConstant @ VMaxの形式で最大電圧値が示されています。定電圧での動作仕様は、同様にVConstant @ IMaxの形式で示されています。コイルの温度変化は加速度の直線性に影響します。そのため、デューティサイクル100%においてコイルの動作温度が平衡状態に到達するまでの時間を示すグラフを提示しています。それらは各ボイスコイルアクチュエータの型番横の青いInfoアイコン(![]() )からご覧いただけます。

)からご覧いただけます。

| Constant Current Operating Specificationsa | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Item # | VC063(/M) | VC063B(/M) | VC125(/M) | VC125B(/M) | VC125C(/M) | VC190(/M) | VC250(/M) | VC380(/M) | VC500(/M) | VC625(/M) | |

| Coil Operating Temperatureb,c | Duty Cycle | ||||||||||

| 60 °C | 10% | 2.15 A @ 4.95 V | 2.55 A @ 5.10 V | 1.80 A @ 7.10 V | 2.30 A @ 7.10 V | 2.45 A @ 18.40 V | 1.80 A @ 9.35 V | @ 14.30 V | 1.60 A @ 11.85 V | @ 18.45 V | @ 19.75 V |

| 50% | 1.00 A @ 2.35 V | 1.59 A @ 3.15 V | 0.95 A @ 3.55 V | 1.15 A @ 3.65 V | 1.30 A @ 9.75 V | 0.90 A @ 4.95 V | 1.05 A @ 7.30 V | 0.85 A @ 6.30 V | 0.90 A @ 9.45 V | 0.95 A @ 10.25 V | |

| 100% | 0.80 A @ 1.85 V | 1.15 A @ 2.50 V | 0.70 A @ 2.65 V | 0.95 A @ 3.00 V | 0.85 A @ 6.30 V | 0.65 A @ 3.50 V | 0.75 A @ 5.35 V | 0.70 A @ 5.05 V | 0.65 A @ 6.90 V | 0.70 A @ 7.40 V | |

| 100 °C | 10% | 2.95 A @ 8.20 V | 3.90 A @ 9.35 V | 2.75 A @ 11.85 Vd | 3.60 A @ 12.80 V | 3.35 A @ 27.80 V | 2.55 A @ 15.50 V | 3.05 A @ 24.85 Vd | 2.35 A @ 20.20 V | 2.50 A @ 30.35 Vd | 2.60 A @ 30.35 V |

| 50% | 1.35 A @ 3.60 V | 2.05 A @ 4.70 V | 1.35 A @ 5.80 V | 1.85 A @ 6.80 V | 1.70 A @ 14.00 V | 1.30 A @ 8.05 V | 1.55 A @ 12.30 V | 1.20 A @ 10.10 V | 1.25 A @ 15.10 V | 1.35 A @ 16.85 V | |

| 100% | 1.10 A @ 3.05 V | 1.45 A @ 3.50 V | 1.05 A @ 4.45 V | 1.35 A @ 4.80 V | 1.25 A @ 10.45 V | 0.95 A @ 5.80 V | 1.15 A @ 9.30 V | 0.90 A @ 7.60 V | 0.95 A @ 11.40 V | 0.95 A @ 11.80 V | |

| Constant Voltage Operating Specificationsa | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Item # | VC063(/M) | VC063B(/M) | VC125(/M) | VC125B(/M) | VC125C(/M) | VC190(/M) | VC250(/M) | VC380(/M) | VC500(/M) | VC625(/M) | |

| Coil Operating Temperatureb,c | Duty Cycle | ||||||||||

| 60 °C | 10% | 4.85 V @ 2.00 Ad | 7.00 V @ 2.95 Ad | 7.10 V @ 1.85 A | 7.15 V @ 2.10 Ad | 17.10 V @ 2.30 Ad | 9.30 V @ 1.75 Ad | 14.40 V @ 2.05 Ad | 13.45 V @ 1.75 Ad | 18.20 V @ 1.75 Ad | 19.95 V @ 1.85 Ad |

| 50% | 2.25 V @ 0.90 A | 3.25 V @ 1.65 A | 3.75 V @ 1.10 A | 3.80 V @ 1.15 A | 8.80 V @ 1.15 A | 5.00 V @ 0.95 A | 7.35 V @ 1.00 A | 6.25 V @ 0.85 A | 9.25 V @ 0.85 A | 10.15 V @ 0.95 A | |

| 100% | 1.80 V @ 0.75 A | 2.50 V @ 1.05 A | 2.75 V @ 0.70 A | 2.80 V @ 0.85 A | 6.30 V @ 0.85 A | 3.50 V @ 0.65 A | 5.40 V @ 0.75 A | 5.00 V @ 0.65 A | 6.85 V @ 0.65 A | 7.50 V @ 0.70 A | |

| 100 °C | 10% | 6.95 V @ 2.50 Ad | 8.90 V @ 3.65 Ad | 11.35 V @ 2.65 Ad | 12.80 V @ 3.50 Ad | 26.00 V @ 3.15 Ad | 15.55 V @ 2.50 Ad | 24.80 V @ 3.00 Ad | 19.00 V @ 1.80 Ad | 29.60 V @ 2.45 Ad | 31.60 V @ 2.60 Ad |

| 50% | 3.30 V @ 1.15 A | 4.50 V @ 1.90 A | 5.85 V @ 1.50 A | 6.65 V @ 1.80 A | 13.95 V @ 1.70 A | 8.05 V @ 1.30 A | 12.30 V @ 1.50 A | 9.55 V @ 1.10 A | 14.95 V @ 1.20 A | 16.00 V @ 1.30 A | |

| 100% | 2.60 V @ 0.95 A | 3.35 V @ 1.40 A | 4.25 V @ 1.00 A | 4.80 V @ 1.30 A | 9.75 V @ 1.20 A | 5.85 V @ 0.95 A | 9.30 V @ 1.15 A | 7.15 V @ 0.85 A | 11.10 V @ 0.90 A | 11.85 V @ 0.95 A | |

| SM05 Threading: Ø1/2" Lens Tubes, 16 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 0.535"-40.0 UNS-2A | Internal Thread, 0.535"-40.0 UNS-2B | ||

| Max Major Diameter | 0.5340" | Min Major Diameter | 0.5350" |

| Min Major Diameter | 0.5289" | Min Pitch Diameter | 0.5188" |

| Max Pitch Diameter | 0.5178" | Max Pitch Diameter | 0.5230" |

| Min Pitch Diameter | 0.5146" | Min Minor Diameter (and 83.3% of Thread) | 0.508" |

| Max Minor Diameter | 0.5069" | Max Minor Diameter (and 64.9% of Thread) | 0.514" |

| RMS Threading: Objective, Scan, and Tube Lenses | |||

|---|---|---|---|

| External Thread, 0.800"-36.0 UNS-2A | Internal Thread, 0.800"-36.0 UNS-2B | ||

| Max Major Diameter | 0.7989" | Min Major Diameter | 0.8000" |

| Min Major Diameter | 0.7934" | Min Pitch Diameter | 0.7820" |

| Max Pitch Diameter | 0.7809" | Max Pitch Diameter | 0.7866" |

| Min Pitch Diameter | 0.7774" | Min Minor Diameter (and 83.3% of Thread) | 0.770" |

| Max Minor Diameter | 0.7688" | Max Minor Diameter (and 64.9% of Thread) | 0.777" |

| C-Mount Threading: Machine Vision Lenses, CCD/CMOS Cameras | |||

|---|---|---|---|

| External Thread, 1.000"-32.0 UN-2A | Internal Thread, 1.000"-32.0 UN-2B | ||

| Max Major Diameter | 0.9989" | Min Major Diameter | 1.0000" |

| Min Major Diameter | 0.9929" | Min Pitch Diameter | 0.9797" |

| Max Pitch Diameter | 0.9786" | Max Pitch Diameter | 0.9846" |

| Min Pitch Diameter | 0.9748" | Min Minor Diameter (and 83.3% of Thread) | 0.966" |

| Max Minor Diameter | 0.9651" | Max Minor Diameter (and 64.9% of Thread) | 0.974" |

| SM1 Threading: Ø1" Lens Tubes, 30 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 1.035"-40.0 UNS-2A | Internal Thread, 1.035"-40.0 UNS-2B | ||

| Max Major Diameter | 1.0339" | Min Major Diameter | 1.0350" |

| Min Major Diameter | 1.0288" | Min Pitch Diameter | 1.0188" |

| Max Pitch Diameter | 1.0177" | Max Pitch Diameter | 1.0234" |

| Min Pitch Diameter | 1.0142" | Min Minor Diameter (and 83.3% of Thread) | 1.008" |

| Max Minor Diameter | 1.0068" | Max Minor Diameter (and 64.9% of Thread) | 1.014" |

| SM30 Threading: Ø30 mm Lens Tubes | |||

|---|---|---|---|

| External Thread, M30.5 x 0.5 – 6H/6g | Internal Thread, M30.5 x 0.5 – 6H/6g | ||

| Max Major Diameter | 30.480 mm | Min Major Diameter | 30.500 mm |

| Min Major Diameter | 30.371 mm | Min Pitch Diameter | 30.175 mm |

| Max Pitch Diameter | 30.155 mm | Max Pitch Diameter | 30.302 mm |

| Min Pitch Diameter | 30.059 mm | Min Minor Diameter (and 83.3% of Thread) | 29.959 mm |

| Max Minor Diameter | 29.938 mm | Max Minor Diameter (and 64.9% of Thread) | 30.094 mm |

| SM1.5 Threading: Ø1.5" Lens Tubes | |||

|---|---|---|---|

| External Thread, 1.535"-40 UNS-2A | Internal Thread, 1.535"-40 UNS-2B | ||

| Max Major Diameter | 1.5339" | Min Major Diameter | 1.535" |

| Min Major Diameter | 1.5288" | Min Pitch Diameter | 1.5188" |

| Max Pitch Diameter | 1.5177" | Max Pitch Diameter | 1.5236" |

| Min Pitch Diameter | 1.5140" | Min Minor Diameter (and 83.3% of Thread) | 1.508" |

| Max Minor Diameter | 1.5068" | Max Minor Diameter (and 64.9% of Thread) | 1.514" |

| SM2 Threading: Ø2" Lens Tubes, 60 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 2.035"-40.0 UNS-2A | Internal Thread, 2.035"-40.0 UNS-2B | ||

| Max Major Diameter | 2.0338" | Min Major Diameter | 2.0350" |

| Min Major Diameter | 2.0287" | Min Pitch Diameter | 2.0188" |

| Max Pitch Diameter | 2.0176" | Max Pitch Diameter | 2.0239" |

| Min Pitch Diameter | 2.0137" | Min Minor Diameter (and 83.3% of Thread) | 2.008" |

| Max Minor Diameter | 2.0067" | Max Minor Diameter (and 64.9% of Thread) | 2.014" |

| SM3 Threading: Ø3" Lens Tubes | |||

|---|---|---|---|

| External Thread, 3.035"-40.0 UNS-2A | Internal Thread, 3.035"-40.0 UNS-2B | ||

| Max Major Diameter | 3.0337" | Min Major Diameter | 3.0350" |

| Min Major Diameter | 3.0286" | Min Pitch Diameter | 3.0188" |

| Max Pitch Diameter | 3.0175" | Max Pitch Diameter | 3.0242" |

| Min Pitch Diameter | 3.0133" | Min Minor Diameter (and 83.3% of Thread) | 3.008" |

| Max Minor Diameter | 3.0066" | Max Minor Diameter (and 64.9% of Thread) | 3.014" |

| SM4 Threading: Ø4" Lens Tubes | |||

|---|---|---|---|

| External Thread, 4.035"-40 UNS-2A | Internal Thread, 4.035"-40.0 UNS-2B | ||

| Max Major Diameter | 4.0337" | Min Major Diameter | 4.0350" |

| Min Major Diameter | 4.0286" | Min Pitch Diameter | 4.0188" |

| Max Pitch Diameter | 4.0175" | Max Pitch Diameter | 4.0245" |

| Min Pitch Diameter | 4.0131" | Min Minor Diameter (and 83.3% of Thread) | 4.008" |

| Max Minor Diameter | 4.0066" | Max Minor Diameter (and 64.9% of Thread) | 4.014" |

| Posted Comments: | |

Hyojeong Shon

(posted 2024-07-31 15:50:35.54) Hi, Thorlabs. Could you please give some information about its typical response time of "VC063/M", if possible?

And could you also provide the information about recommended controller and Amp.?

Thank you! cdolbashian

(posted 2024-08-30 11:28:54.0) Thank you for reaching out to us with this inquiry. This device is a purely analog inductive circuit driving a ~7gram mass. The response time would depend on your driving parameters directly. I have contacted you regarding this, as well as regarding some recommendations for controller and amplifier. Viacheslav Slesarenko

(posted 2024-05-07 17:33:29.82) Hi Thorlabs,

We are trying to build a small testing setup consisting of two voice coils. While the VC125C/M options are very good in respect to stroke and force, we are bit lost regarding suitable motion controller and amplifier. Could you please give some recommendations? Thanks a lot! cdolbashian

(posted 2024-05-10 03:51:57.0) Thank you for reaching out to us with this inquiry. I have contacted you directly to discuss some basic recommendations and usage tips. user

(posted 2024-02-29 13:22:54.4) Hi Thorlabs,

I am currently using your VC125B/M and VC380/M. I am trying to drive them with a H-Bridge motor driver (originally for a bldc motor) and want to identify the system over the current's step response. Have you done something similar which's documentation you could provide? Or do you have any other documents regarding the mathematical model or system identification that you could send me?

Thank you in advance. jpolaris

(posted 2024-03-01 06:56:44.0) Thank you for contacting Thorlabs. I have reached out to you directly with raw force over travel data for VC125B/M and VC380/M when driven at 1 A. If you know the mass load being driven by the coil, you can use the force data along with the kinematics equations to calculation motion. user

(posted 2023-12-04 03:26:26.747) Hi,

Could you also provide the information about controller/amp recommendations? Thanks. cdolbashian

(posted 2023-12-11 10:46:04.0) Thank you for reaching out to us with this inquiry. As this is a current-driven device with very low resistance, we recommend using a function generator in combination with a unity-amplifier, or using a benchtop current supply with modulation options. I have contacted you directly with some recommendations. user

(posted 2023-11-12 21:39:05.373) Hi, can you recommend a controller/ driver for your VCAs with current control? jdelia

(posted 2023-11-13 02:49:03.0) Thank you for contacting Thorlabs. I have reached out to you directly regarding controller/amp recommendations. user

(posted 2023-08-15 16:01:29.14) Hi,

We are interested in this product to stabilize our laser by partially blocking the laser beam based the PID loop using the current reading (~100 uA) of a detector device. In this case, would you recommend having a separate current amplifier/driver?

Also, could you provide a Solidworks file with a lower (2021) version? I cannot open the file as it's a future version file.

Thanks a lot for your help! ksosnowski

(posted 2023-08-30 04:16:46.0) Thank you for reaching out to us. Common photodiode max output currents are fairly low so transimpedance amplifier can be useful to convert this to a voltage with high gain while also preserving the sensor bandwidth. Optical feedback is one method of creating a closed-loop system with the voice coils. It would otherwise require a fairly high impedance input on any driver to reach a 5V signal swing with 100uA current, and if using the input impedance as a load directly then that will lower the RC time constant of the photodiode resulting in a lower bandwidth. Depending on the exact gain and bandwidth necessary our amplifiers like AMP120 may be a solution. I have reached out directly to discuss this application and other file versions in further detail. user

(posted 2023-07-24 09:30:50.067) Hello, please recommend controller/amplifier for these coils jdelia

(posted 2023-07-24 01:12:44.0) Thank you for contacting Thorlabs. I have reached out to you directly regarding function generator and unity amp recommendations. Andres Gomez

(posted 2023-07-11 18:09:57.39) Hello, I wanted to know if I can control the voice coil with a raspberry pi and with the following amplifier "15A 400W PWM Supported MOSFET Switching Module".

Thank cdolbashian

(posted 2023-07-21 03:25:23.0) Thank you for reaching out to us with this inquiry. I have contacted you directly to share our experienced when driving these devices. user

(posted 2023-07-12 11:32:12.54) Dear thorlabs,

Hellow, I am interested in your voice coil. I have a function generator, but don't have any current source. So, could you please recommend any current source to control your device? Do you have any dedicated voice coil controller?

Thanks cdolbashian

(posted 2023-07-21 03:25:31.0) Thank you for reaching out to us. When we tested this device, we used OPA548 amplifier from Texas Instruments with an analog function generators as a driver in our development of this device. A similar, stable, current source should be appropriate. user

(posted 2023-07-10 21:53:42.097) Hello, I wanted to know if you can control l voice coil by means of a raspberry pi and current amplifiers and if not so they recommend me to control the movement. And this actuator "motor driver 810-01" if it is compatible with the voice coil.

Thank you. cdolbashian

(posted 2023-07-21 03:36:44.0) Thank you for reaching out to us. I have contacted you directly to share the configuration we use when driving this device, as I am unsure as to what "motor driver 810-01" is referring. user

(posted 2023-05-20 13:07:57.87) Hello, I wanted to know what is the positioning resolution of the device? and what type of controller do you use? cdolbashian

(posted 2023-05-26 12:05:13.0) Thank you for reaching out to us Benjamin. This device is nominally analog, and the position of the actuator moves as a function of applied current. Depending on the quality of your current control, you will have varying quality of positional resolution. Lee Kyesung

(posted 2023-05-15 16:41:24.14) Is it possible to reciprocate in an axis perpendicular to the direction of gravity without contact between the moving and fixed world? Thanks ksosnowski

(posted 2023-05-15 04:17:57.0) Hello Lee, thanks for reaching out to Thorlabs. We have used the voice coils in this orientation before, although it does require a mount that will maintain the coil separation. Currently we have one product series VCFL35(/M) which incorporates the VC063/M voice coil into a flexure mount for scanning applications. Alex Barker

(posted 2023-04-04 13:14:35.53) Hi there,

I can't open the solidworks files for the voice coils as the version is newer than my version of solidworks.

Do you have solidworks part files (*.sldprt) for VC250 and VC500 for solidworks version 2019 SP5.0 or earlier?

Thanks very much

-Alex cdolbashian

(posted 2023-04-13 10:57:32.0) Thank you for reaching out to us Alex! While we do not have an older version of this Solidworks file, we do also have .STEP files in the same location, which should be insensitive to the version of Solidworks used. Klaus Becker

(posted 2023-03-14 12:04:23.243) Hello,

could you perhaps recommend a priceworthy frequency generator / amplifier which works with the VC063/M voice coil actuator?

best regards,

Klaus jdelia

(posted 2023-03-14 09:20:34.0) Thank you for contacting Thorlabs. I have reached out to you directly regarding function generator and unity amp recommendations. Taeguk Um

(posted 2023-02-18 23:45:20.573) Hi, I'm taeguk Um in KAIST, KOREA.

I want to more about this product.

In this product, how fast can it move?

Also, if i input sinusoidal voltage, can i get reciprocating linear motion?

Sincerely

Taeguk Um jdelia

(posted 2023-02-23 01:27:47.0) Thank you for contacting Thorlabs. While we do not have any speed data for these actuators, you can use the force vs travel plot we show on the website to extrapolate the acceleration and speed of the actuator using the kinematic equations. The speed will depend on the mass attached to the actuator. To answer your second question, yes, applying a sinusoidal voltage wave will result in linear motion. Rahul Yadav

(posted 2022-12-14 21:02:16.67) I purchased Voice coil actuator(VC125/M) to control the movement in z- direction. So, I have few questions regarding that

1) How to operate it as if I'm directly giving signal from signal generator it stays upto some voltage and then suddenly shoots up. So, please tell me how to operate it precisely as I need precision of 20 um.

2) And if there is any components or driver to run these actuators please mention them as I'm getting difficulty in running these actuators.

Regards,

Rahul cdolbashian

(posted 2022-12-28 09:59:24.0) Thank you for reaching out to us Rahul! It is important to ensure that there is current flowing to your device. Since this device works via current-generated magnetic fields, simply providing a voltage supply will not necessarily ensure full functionality. I have contacted you directly to troubleshoot this issue and attempt to figure out exactly how to make this work for your application. user

(posted 2022-12-11 14:24:19.69) Hi, we are interested in your voice coil actuators and want to know if any controller, driver or amplifier are required for operation. If so, do you recommend any instruments

(and their brand names) for the actuator control and operation? Thank you. jdelia

(posted 2022-12-12 08:15:43.0) Thank you for contacting Thorlabs. Yes, you would need a controller in order to driver our voice coils. While we do not currently offer a driver, we suggest using a unity amp in conjunction with a signal generator. I have contacted you directly regarding amp recommendation. Srinivasan Manivannan

(posted 2022-12-05 14:31:26.917) Is this product Ultra high vacuum compactable?

And do we need any controller for this? jdelia

(posted 2022-12-05 02:24:32.0) Thank you for contacting Thorlabs. Unfortunately, our voice coil actuators are not considered vacuum compatible. You would need a controller in order to drive them. While we do not currently offer a driver, we suggest using a unity amp in conjunction with a signal generator. I have contacted you directly regarding amp recommendation. Santosh C R

(posted 2022-10-28 15:07:19.98) Hi

i am a doctoral research scholar at SSSIHL, India working on ultrafast fiber lasers. i am interested in using yourr

VC500/M to set up an interferrometer experiment. i would like to know how do you mount the voice coil actuator on a regular optomechanical mount?

most importantly, how do you drive the voice coil actuator to perform a simple micelson interfermeter experiment? ksosnowski

(posted 2022-10-28 03:42:09.0) Hello Santosh, thanks for reaching out to Thorlabs. We have not designed mounts for all of the voice coil sizes, however VCFL35 is an example of a flexure-mounted unit we've designed. The webpage for VCFL35 has a brief video and Application Guide covering Michelson Interferometry as an example. Generally a triangle function is used to drive the coil, we do not have a driver for these however we have used the OPA548 amplifier from Texas Instruments with function generators as a driver in our development. I have reached out directly to discuss this further. Nick Mascolo

(posted 2022-10-11 11:15:54.2) Good Morning,

is there information available for what frequency range these products are optimized for? Or is there information about the acceleration of these products? cdolbashian

(posted 2022-10-14 03:48:38.0) Thank you for reaching out to us with this inquiry Nick! As the motion of these devices are driven by currents converted to forces due to the winding the coils of wire, we do provide the force which each of these devices can deliver as a function of displacement (see graph in tables above). This determines the maximum acceleration (when adding mass to the component in motion) as well as frequency, as the turning points of the device will require large accelerations to complete the motion. Depending on the Mass and driving waveform it is certainly possible to estimate a max driving frequency though we have not explicitly tested it. Oscar Martinez

(posted 2021-11-17 10:57:03.793) Do you provide a controller for the voice coil? jgreschler

(posted 2021-11-18 11:04:13.0) Thank you for reaching out to Thorlabs. Unfortunately, we don't offer a controller for our voice coil actuators at the moment. That being said, we currently have a controller in development scheduled for release in Q2 2022. user

(posted 2021-09-09 21:37:52.913) We wish to buy one of these products to perform experiments and we have some queries regarding some of the possible applications

First which part of the coil moves, is it the coil assembly or the magnet assembly? Can I attach a 30g mirror on the magnet assembly and expect it to oscillate about a mean position of frequency 1kHz. Will the coil be able load this mirror in the horizontal position? What resolution of movement can we expect (we require a max displacement of 60micrometers). At what voltage can we operate this coil. azandani

(posted 2021-09-23 03:54:57.0) Hello, thank you for contacting Thorlabs. Allow me to address each of your questions individually. Depending on how the voice coil is mounted, either the magnet or the coil can be the moving component. In most cases, the magnet will be the moving body so the wires do not get fatigued from constant movement. Your second question is more application dependent, but if you are looking to use it as a scanning device, a standalone voice coil will not yield ideal results. It is essentially just a motor and would need to be integrated and designed into a scanning device. The motion of a mirror mounted to the end of the voice coil would not provide constant motion on the surface of the mirror. That being said, these unfortunately do not have an encoder, so the movement resolution would be dependent on the resolution of the voltage and current applied. Guoxing Gu

(posted 2021-03-14 01:25:55.75) I would like to attach a 10 g part on the voice coil motor and use it as a vertical stage to move the part down, what acceleration can be achieved? what is the response time? asundararaj

(posted 2021-04-01 01:49:53.0) Thank you for contacting Thorlabs. The voice coil actuators have not been formally tested for the achievable acceleration and response time. We are looking to conduct more tests on these in the coming months and will publish any repeatable specs. Chan Leh Mun

(posted 2021-01-18 02:28:36.843) Hi

What is the max current can be use?

I thinking of using 3A for maybe 5 seconds to press a part down during UV curing. Then the coil should be at 1A current for another 5 seconds. This coil use to drive a Z axis for pick & place application.

I wish to have up to 11.5N of force available during pressing down for 5 seconds. YLohia

(posted 2021-02-16 02:07:39.0) Hello, thank you for contacting Thorlabs. The voice coils have not been tested up to 3 A and the data we have is at 100% duty cycle. The voice coil got up to a temp of 24.5°C in the first 15 seconds of operation at 1 A and then rose to 33 °C over the following 15 seconds (Total 30 seconds of operation at 1 A). The maximum current we specify is 1.9 A. Based on the data we have at the moment and the time that you're looking to run the coil, we believe it can withstand your operating conditions but we cannot guarantee this due to the lack of formal testing with these parameters, but we cannot provide any guarantees at the moment. |

| Item #a | Info | Coil Assembly Threada | Mounting Taps | Force Constantb | Travel | Coil Assembly Mass | Magnet Assembly Mass | Coil Resistance | Coil Inductance |

|---|---|---|---|---|---|---|---|---|---|

| VC063 | SM05 (0.535"-40) | 4-40 | 0.74 N/A (Raw Data) | 1/4" (6.4 mm) | 7 g | 7 g | 1.9 Ω | 167 µH | |

| VC063/M | M3 | ||||||||

| VC063B | SM1 (1.035"-40) | 4-40 | 1.5 N/A (Raw Data) | 1/4" (6.4 mm) | 13 g | 25 g | 1.9 Ω | 225 µH | |

| VC063B/M | M3 | ||||||||

| VC125 | SM05 (0.535"-40) | 4-40 | 0.89 N/A (Raw Data) | 1/2" (12.7 mm) | 9 g | 10 g | 3.5 Ω | 316 µH | |

| VC125/M | M3 | ||||||||

| VC125B | SM1 (1.035"-40) | 4-40 | 1.6 N/A (Raw Data) | 1/2" (12.7 mm) | 16 g | 34 g | 2.9 Ω | 425 µH | |

| VC125B/M | M3 | ||||||||

| VC125C | SM2 (2.035"-40) | Magnet: 1/4"-20 Coil: 8-32 (2 Places) | 12.4 N/A (Raw Data) | 1/2" (12.7 mm) | 71 g | 324 g | 6.1 Ω | 2950 µH | |

| VC125C/M | Magnet: M6 Coil: M4 (2 Places) | ||||||||

| VC190 | SM05 (0.535"-40) | 4-40 | 0.8 N/A (Raw Data) | 3/4" (19.1 mm) | 9 g | 11 g | 4.6 Ω | 585 µH | |

| VC190/M | M3 | ||||||||

| VC250 | SM1 (1.035"-40) | Magnet: 1/4"-20 Coil: 8-32 (2 Places) | 3.84 N/A (Raw Data) | 1" (25.4 mm) | 38 g | 97 g | 5.1 Ω | 1675 µH | |

| VC250/M | Magnet: M6 Coil: M4 (2 Places) | ||||||||

| VC380 | SM1 (1.035"-40) | Magnet: 1/4"-20 Coil: 4-40 | 2 N/A (Raw Data) | 1.5" (38.1 mm) | 26 g | 62 g | 7.2 Ω | 1155 µH | |

| VC380/M | Magnet: M6 Coil: M3 | ||||||||

| VC500 | SM1 (1.035"-40) | Magnet: 1/4"-20 Coil: 8-32 (2 Places) | 3.99 N/A (Raw Data) | 2" (50.8 mm) | 51 g | 153 g | 8.5 Ω | 3274 µH | |

| VC500/M | Magnet: M6 Coil: M4 (2 Places) | ||||||||

| VC625 | SM30 (M30.5 x 0.5) | Magnet: 1/4"-20 Coil: 8-32 (2 Places) | 6.01 N/A (Raw Data) | 2.5" (63.5 mm) | 78 g | 369 g | 9.8 Ω | 4328 µH | |

| VC625/M | Magnet: M6 Coil: M4 (2 Places) |

Products Home

Products Home

ボイスコイルアクチュエータ

ボイスコイルアクチュエータ