接着剤用注入器

- Long Pot Life Epoxies

- High Glass Transition Temperature Epoxies

- 5-Minute Epoxies

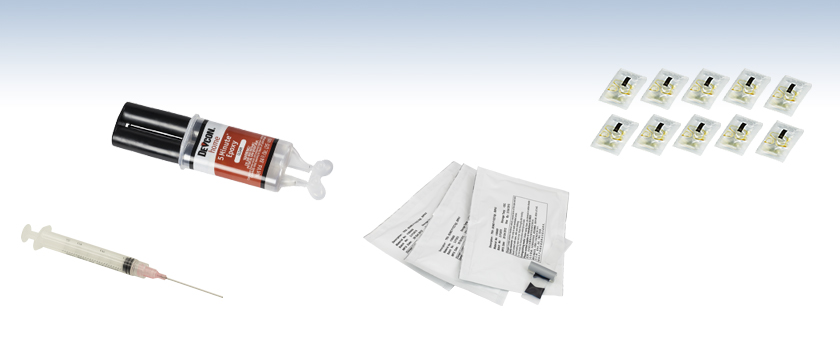

MS403-10

Epoxy Syringe

G14250

General Purpose 5-Minute Epoxy

F112

Long Pot Life Epoxy

353NDPK

High-Temperature Epoxy

Please Wait

接着剤用の注入器(シリンジ)をご用意しています。詳しくは下の製品紹介をご覧ください。また、UV硬化光学素子用接着や接着剤調合キットもご提供しております。

| Item # | F112 | F120 | F123 | 353NDPKa |

|---|---|---|---|---|

| Color, Cured | Dark Blue | Clear/Colorless (Part A) Clear/Yellow Tint (Part B) |

Reddish-Amberb | Dark Red |

| Specific Gravity, Cured | 1.2 | 1.16 (Part A) 1.05 (Part B) |

1.2 | 1.20 (Part A) 1.02 (Part B) |

| Index of Refraction | 1.51 | 1.5459 @ 589 nm | 1.56 | 1.5694 @ 589 nm |

| Viscosity, cPs, Mixed | 1800 | N/A | 4000 | 3000 - 5000 |

| Thixotropic Index | 1.0 | N/A | 1.0 | N/A |

| Operating Temperature Range | -60 to 120 °C | Cont: -55 to 175 °C Inter: -55 to 275 °C |

-60 to 175 °C | Cont: -55 to 250 °C Inter: -55 to 350 °C |

| Hardness, Shore D | 86 | 80 | 87 | 85 |

| Mix Ratio, pbw, Resin/Hardener | 100/30 | 2/1 | 100/10 | 10:1 |

| Glass Transition (Tg), Ultimate | 102 °C | 56 °C | 120 °C | ≥90 °C |

| Water Absorption | 0.07% | N/A | 0.004% | N/A |

| Coefficient of Expansion | 6.20 x 101 cm/cm/°C | N/A | >Tg: 2.03 x 102 ppm/°C <Tg: 6.31 x 101 ppm/°C |

>Tg: 54 x 10-6 in/in/°C <Tg: 206 x 10-6 in/in/°C |

| Dielectric Strength | N/A | N/A | 400 V/mil | N/A |

| Dielectric Constant | N/A | N/A | N/A | 3.17 (1 kHz @ 23 °C) |

| Pot Life | 2 g, 30 min | <5 min | 4 hr | ≤3 hr |

| Working Life | 2 g, 1 hr | N/A | N/A | N/A |

| Cure Schedule | 24 hr @ 25 °C or 1 hr @ 65 °C or 15 min @ 90 °C |

30 min @ 23 °C (Minimum) |

5 min @ 100 °C or 2 min @ 120 °C or 1 min @ 150 °C |

30 min @ 80 °C 10 min @ 100 °C 5 min @ 120 °C 1 min @ 150 °C |

| Posted Comments: | |

Md Omar Faruk Rasel

(posted 2024-05-13 11:52:15.477) I am planning to build a fiber-to-fiber assembly on the Glass substrate using UV epoxy. I am thinking about F112 or F120. Could you please suggest which one (F112 or F120) is suitable for attaching the fiber to the Glass substrate?

I am looking forward to hearing from you. Thank you.

Omar cdolbashian

(posted 2024-05-21 11:18:11.0) Thank you for reaching out with this inquiry. The epoxies you have referenced here are both 2-part air-curable epoxy, rather than UV curable epoxies. If you are looking for something which will attach the Glass of the fiber to a glass substrate, I would suggest the UV Optical Adhesive NOA61. I have contacted you directly to discuss other options and your application restrictions. Steve Green

(posted 2022-05-31 09:02:27.733) Hi

Could you please contact the supplier of H112 product. Their datasheet is wrong I doubt that an epoxy with a Tg=102°C, could have an expansion of 62 cm/cm/°C. When all other similar materials 10 to 100 ppm cm/cm/°C.

Best regards

Steve cdolbashian

(posted 2022-09-19 10:39:44.0) Thank you for reaching out to us Steve. I have reached out to the vendor as well as investigated information provided directly by them. The information we have/provide is consistent with their own. DS Chen

(posted 2022-04-05 11:03:12.65) I want to put a SM fiber in cryostat at 4K. I am wondering if F112 epoxy cured ferrule compatible with cryo applications, like thermal expansions of different parts (epoxy, silica and ceramic ferrule) or the gas leaking of epoxy. Thank you. jgreschler

(posted 2022-04-06 10:09:18.0) Thank you for reaching out to Thorlabs. The operating temperature range for F112 is -60-120C, per the information on our specs tab of this page. Unfortunately that is the lowest temperature any of our fiber epoxies is rated to, which is well above 4 kelvin. Lorinda x

(posted 2022-03-18 09:48:42.57) I read that the fibre polymer coatings typically should not be exposed to more than 80ºC to avoid degradation, but the curing temperature of many of these epoxies are higher than 100ºC. Please advise on how to cure the epoxied connector without simultaneously damaging the fibre coating that may be in contact? Is a special oven required? jgreschler

(posted 2022-03-22 10:07:15.0) Thank you for contacting Thorlabs. For the majority of our fiber products the polymer coating is stripped off the cladding before connectorization, which provides an insulating buffer between the epoxy cure and the coating. There are some specialty fibers for which this is complicated, I have reached out to you directly to discuss your specific application. user

(posted 2021-12-09 15:21:40.27) Is it possible to offer lower quantities of this epoxy. Normally one needs up to two packets for one fiber. We baught last year a set of ten packets, used two and I really don't want to buy again ten when I need just two and one cannot store them longer than one year. jgreschler

(posted 2021-12-09 04:25:44.0) Thank you for reaching out to Thorlabs. I have contacted you directly to discuss any questions you may have. Jussi Puustinen

(posted 2021-11-23 01:29:48.847) Is same product 353ND and your 353NDPK

if i click MFG Spec document, i see 353ND datasheet

What end *PK means? YLohia

(posted 2021-11-23 03:07:23.0) Yes, these are the same parts. The "PK" at the end of the part number refers to "pack" since the part is sold as a 10 pack. TC Lin

(posted 2021-03-04 16:43:48.25) what will be EXP date for 353NDPK? YLohia

(posted 2021-03-15 02:26:09.0) 353NDPK Epoxy has a shelf life of 365 days when stored at 23 °C. This time frame begins on the date the epoxy was packaged at the manufacturer. Upon receipt by the end user, Thorlabs guarantees that the remaining shelf life will be at least 3 months. David Oswald

(posted 2020-09-30 16:25:17.27) It would be very helpful to include in your product description, the dimensions of the needle to determine fit with my application. llamb

(posted 2020-10-01 04:18:04.0) Thank you for your feedback. We will look to update the web presentation to include more dimensions for this syringe. In the meantime, the needle has an inner diameter of Ø0.58mm, an outer diameter of Ø0.9mm, and a length of about 36.5 mm. user

(posted 2019-07-30 10:31:42.027) Dear Support! I need an easily solvable adhesive to polish a proper fiber pigtail. The adhesive must fix fiberglass and ceramic ferrule to each-other during polishing and at the end it must to be dissolved easily to ensure the removal of fiber from the ceramic ferrule. Could you offer me a compliant product? Thanks in advance! YLohia

(posted 2019-07-31 10:49:53.0) Hello, we do not have any recommendations for such an epoxy. For temporarily connectorizing a fiber for the purposes of polishing, we recommend using the BFT1. Armin Schöffmann

(posted 2019-04-01 13:30:51.523) "F112 and F120 Not Intended for Use with TECS Clad Fiber":

- Which room-temp. Epoxy-bond would you recommend for TECS-fibres?

- What problems may arise if F112 is applied, though?

Thanks & best regards. YLohia

(posted 2019-04-16 08:58:24.0) Hello, thank you for contacting Thorlabs. The primary reason why we do not recommend F112 or F120 epoxies is because it is corrosive to the TECS coating and has been known to cause delamination in some cases. The best epoxy choice for all Thorlabs TECS fiber are the thermal cure options; F123 and 353NDPK. sudesh

(posted 2016-05-07 03:59:23.857) pleast mee contac besembeson

(posted 2016-05-10 03:13:08.0) Response from Bweh at Thorlabs USA: I have contacted you regarding any questions you may have. mlippert

(posted 2016-01-14 06:00:16.877) Hello,

I'm using the fast room temp cure resin and often I have the problem, that it starts to heat up already during mixing and starts to solidify within less than a minute. Is there a solution for this problem? jlow

(posted 2016-01-14 02:58:55.0) Response from Jeremy at Thorlabs: The F120 only has a very short pot life for fast curing. If you need longer pot life, we have the F112 which has a 30 minute pot life. jjurado

(posted 2011-06-28 11:47:00.0) Response from Javier at Thorlabs to c.j.lee: Thank you very much for contacting us. Although we currently do not have thermal conductivity specs for our epoxies and other adhesives, we can say that, based on the operating temperatures, the resins for these epoxies are relatively highly thermally conductive (see Specs Tab). Also, some of these epoxies, such as the F112, will absorb water and have hygroscopic properties. I will contact you directly to help you narrow down your choices based on your application's requirements. c.j.lee

(posted 2011-06-28 07:41:09.0) Do you know what the thermal conductivity of the resins are? We were thinking of using it to glue a BBO crystal in place. The crystal must be heated to ~70 degrees and dont want to have problems with the crystal overheating and cracking.

Also, I assume that since it is a epoxy resin that it is not hygroscopic?

Customer Email: c.j.lee@rijnhuizen.nl |

- Easy-to-Use 2 g BIPAX

- Sold in Packages of 10

- F112 and F120 Not Intended for Use with TECS Clad Fiber

F112 Long Pot Life, Room Temperature Cure

The F112 epoxy is an ideal epoxy for making room temperature terminations. Each pack contains enough epoxy for 25 to 30 connectors. The long 30-minute pot life allows many connectors to be produced from one mix. See the Specs tab for details.

F120 Fast Room Temperature Cure

The F120 epoxy provides a combination of fast cures and low shrinkage for high performance fiber optic connections. At room temperature, the connectors are ready for polishing within 1 hour; however, fully matured bonds require 4 to 6 hours. With a pot life of only five minutes, a limited number of connections can be made using one pack. See the Specs tab for details.

F123 Color-Keyed, High-Temperature Cure

This epoxy has a unique three-step color change formulation: unmixed components are light yellow, the mixed color is green/blue, and after the required 100 °C high-temperature cure, the color is a deep reddish-amber. Each pack contains enough epoxy for 25 to 30 connectors. The long four-hour pot life allows many connectors to be produced from one mix. See the Specs tab for details.

Dangerous Goods

The F112, F120, and F123 epoxies are classified as dangerous goods in some countries. Depending on the delivery location, these items may need to be shipped separately from the rest of your order (and possibly with a different carrier) at an additional charge. Please contact our sales department if there are questions or concerns when placing an order for these items.

Shelf Life

When stored at 25 °C, the F112 and F123 Epoxy have a shelf life of 180 days while the F120 Epoxy has one of 365 days. This time frame begins on the date the epoxy was packaged at the manufacturer. Upon receipt by the end user, Thorlabs guarantees that the remaining shelf life will be at least 3 months.

Crystallization

The epoxy resins may crystallize. Prior to mixing, the crystallized material should be warmed between 40 and 60 °C until the crystals dissolve into the solution. Afterwards, cool the material back to room temperature and use as normal.

- Excellent Wicking for Fiber Optic Applications

- High Temperature Epoxy - Can Perform at Constant 250 °C

- Passes NASA Low Outgassing Standard ASTM E595 with Proper Cure

- Color Changes Upon Curing From Amber to Dark Red

- Pot Life ≤3 Hours

- Pre-Measured, 4 g Packs

EPO-TEK 353ND is known industry wide as a high temperature epoxy. This two part, 100% solid, heat curing epoxy can be used in applications requiring constant performance at temperatures up to 250 °C. It can handle 250 °C to 350 °C for brief periods. The epoxy is vacuum compatible and passes NASA low outgassing standard ASTM E595. Thorlabs offers 353ND epoxy in pre-measured, 4-gram packs that provide repeatable performance and eliminate the need for measuring.

Dangerous Goods

Please note that 353NDPK is classified as a dangerous good in some countries. Depending on the delivery location, this item may need to be shipped separately from the rest of your order (and possibly with a different carrier) at an additional charge. This 2-part epoxy is stocked within the USA and Germany. Please contact our sales department if there are questions or concerns when placing an order.

Shelf Life

353NDPK Epoxy has a shelf life of 365 days when stored at 23 °C. This time frame begins on the date the epoxy was packaged at the manufacturer. Upon receipt by the end user, Thorlabs guarantees that the remaining shelf life will be at least 3 months.

- General Purpose, 2-Part Epoxy

- Easy-to-Use Dispenser Ensures Proper Mixing Ratio

Please note that epoxy resins are prone to solidification or crystallization. If this occurs, the product can easily be returned to a liquid state by immersing the tube in warm [approximately 100 °F (38 °C)] water for 30 minutes. Ensure all material is melted prior to use. Allow the resin component to return to room temperature prior to mixing with the hardener.

接着剤用注入器

この注入器の容量は1本3 ccです。1パック10本入りでご提供しており、接着剤の塗布に適した製品です。パック内で2液混合ができるような混合型接着剤の場合、パックの中身を混合した後に注入器に移し替えることで、接着剤を容易に塗布することが可能になります。

注入器や接着剤すべてを適切に処理するには、当社の光ファイバ処理ユニット(FTDU、別売り)をお勧めします。

Products Home

Products Home

ズーム

ズーム

接着剤用注入器

接着剤用注入器