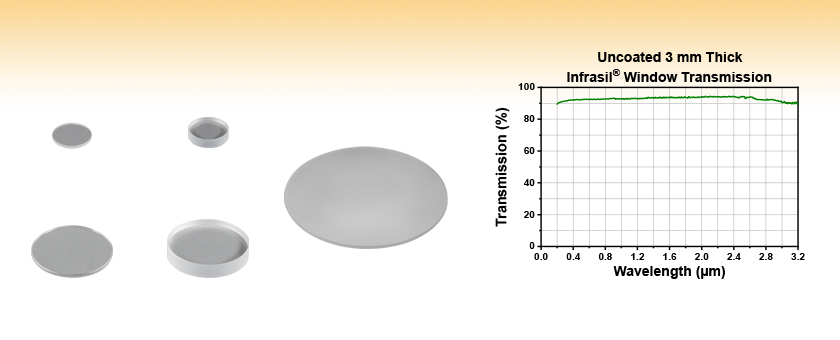

Infrasil®(光学石英)ウィンドウ

- Uncoated Windows for 300 nm - 3 µm

- 1.0, 3.0, or 5.0 mm Thick Windows

- Ø1/2", Ø1", and Ø2" Versions Available

- Offer Enhanced Transmission Above 1 µm

UDP10

(Ø1", 1.0 mm Thick)

UDP053

(Ø1/2", 3.0 mm Thick)

UDP05

(Ø1/2", 1.0 mm Thick)

UDP105

(Ø1", 5.0 mm Thick)

UDP20

(Ø2", 1.0 mm Thick)

Please Wait

| Flat Window Selection Guide | |

|---|---|

| Wavelength Range | Substrate Material |

| 180 nm - 8.0 μm | Calcium Fluoride (CaF2) |

| 185 nm - 2.1 μm | UV Fused Silica |

| 200 nm - 5.0 μm | Sapphire |

| 200 nm - 6.0 μm | Magnesium Fluoride (MgF2) |

| 220 nm to >50 µm | CVD Diamond Windows |

| 230 nm - 1.1 µm | UV Fused Silica, Textured Antireflective Surface |

| 250 nm - 1.6 µm | UV Fused Silica, for 45° AOI |

| 250 nm - 26 µm | Potassium Bromide (KBr) |

| 300 nm - 3 µm | Infrasil® |

| 350 nm - 2.0 μm | N-BK7 |

| 600 nm - 16 µm | Zinc Selenide (ZnSe) |

| 1 - 1.7 µm | Infrasil®, Textured Antireflective Surface |

| 1.2 - 8.0 μm | Silicon (Si) |

| 1.9 - 16 μm | Germanium (Ge) |

| 2 - 5 μm | Barium Fluoride (BaF2) |

| V-Coated Laser Windows | |

50:50の超短パルスレーザ用ビームスプリッタの透過ならびに反射ビームで分散のバランスを取るための1.0 mmウィンドウを用いた推奨構成(50 fs未満のパルスのみ)

特長

- Ø12.7 mm(Ø1/2インチ)、Ø25.4 mm(Ø1インチ)およびØ50.8 mm(Ø2インチ)ウィンドウ

- 厚さ1.0 mm、3.0 mmまたは5.0 mm

- 300 nm~3 µmに平坦な透過率

- UVグレード溶融石英(UVFS)とほぼ同じ材質特性

- 超短パルスにおける分散の調整に適した製品

こちらのコーティング無しのウィンドウは、光学石英ガラスの1種であるInfrasil®†製です。Infrasilは、UVグレード溶融石英(UVFS)とほぼ同じ力学的、光学的特性を有しているため、UV溶融石英の代替品としてよく用いられています。InfrasilはUV溶融石英と比べ、1380 nm付近においてより高い内部透過率を有し、UV域から中赤外域においてはより平坦な透過特性を有します。また分散特性はほぼ同じです。上のグラフは、サンプルとして抽出したウィンドウの200 nm~3.2 µmにおける全透過率を示しています。

なお厚さ1 mmのウィンドウ(型番UDP05など)はほかのウィンドウよりも薄く、厚みのある製品に比べて繊細ですのでご注意ください。また、標準的な止めネジ(セットスクリュ)型の光学マウントには薄すぎるため取り付けられません。ウィンドウを光学マウントに取り付ける時には、固定式光学マウントの場合と同様に、固定リングを用いて固定してください。

超短パルスでの利用

厚さ1.0 mmのウィンドウを超短パルスレーザ用ビームスプリッタUFBS5050に使用すると、ビームスプリッタの透過ならびに反射アームの群遅延分散をほぼ同じにすることができます。 その他の超短パルスレーザ用ビームスプリッタの場合、厚さ1.0 mmのInfrasilウィンドウでは厳密な分散のバランスを取ることはできませんが、2つのビーム間の分散のバランスを向上させることは可能です。当社の厚さ4.0 mmのビームスプリッタに厚さ3.0 mmm(型番UDP053)または5.0 mmm(型番UDP105)のInfrasilウィンドウを使用して、ある程度の分散を補償することができますが、このビームスプリッタ向けに特別に設計されているわけではありません。

†Infrasilは、Heraeus Quarzglas社の登録商標です。

| Posted Comments: | |

Carolina Barrientos

(posted 2021-02-03 21:50:38.763) Dear All,

I write from Aerial Photogrammetric Service of Chilean Air Force since we need to modify 2 G-IV for photogrammetry and remote sensing soon (this and next year). We have some doubts regarding the optical window and we are visualizing Infrasil as possible material.

For our digital camera we have a sort of requirements, The window should be around 60x 60 cm, fullfil M, Mil Specs MIL-W-1366F (ASG) Oct. 1975, S/D 80/50 and antireflective coating (e.g. RYN-1, RYN-B, AR106).

However we are considering a hyperspectral VNIR-SWIR for the near future. Some providers have suggested S/D 60/40 and the requirements of transmittance along the spectral range, however we have a doubt regarding the coatings. The above mentioned work up to ~1000nm and we would need to know if you provide another option suitable for the sensor we have and if having a coating or not would interfere with a hyperspectral sensor.

I would be very gratefull for any feedback

Carolina Barrientos Gajardo

Aerial Photogrammetric Service

Chilean Air Force

E-mail: carolina.barrientos@saf.cl

Web: www.saf.cl

56- 02-29769360

Av. Diego Barros Ortiz Nº 2300 – Aeropuerto Arturo Merino Benítez - Pudahuel

Skype: carolina.barrientos.saf YLohia

(posted 2021-02-03 11:22:35.0) Thank you for contacting Thorlabs. Custom optics can be requested by clicking the "Request Quote" button above or by emailing your local Thorlabs Team (in your case techsupport.br@thorlabs.com). We will contact you directly to discuss this further. Abani Nayak

(posted 2019-05-23 10:12:14.667) I would like to have Rectangular shape of Infrasil instead of Circular. Can I get rectangular window of Infrasil with customized length, width or height? YLohia

(posted 2019-05-23 10:06:30.0) Hello, thank you for contacting Thorlabs. We are reaching out to you directly to discuss the possibility of offering a custom option. jarias

(posted 2017-04-03 06:59:16.557) Is it possible to get this window in 2 inches diameter and with AR coating for 1070 nm? tfrisch

(posted 2017-04-19 02:44:03.0) Hello, thank you for contacting Thorlabs. I have contacted you directly concerning more details for a quote. |

| Window Selection Guide (Table Sorted by Wavelength) | |||||

|---|---|---|---|---|---|

| Substrate and Window Type | Wavelength Range | Available AR Coatings | Reflectance over AR Coating Rangea | Transmission Data | Reflectance Data |

| Calcium Fluoride (CaF2): Flat or Wedged | 180 nm - 8.0 μm | Uncoated | - | Raw Data | - |

| -D Coating, 1.65 - 3.0 µm | Ravg < 1.0%; Rabs < 2.0% at 0° AOI | Raw Data | Raw Data | ||

| UV Fused Silica: Flat, Wedged, V-Coated Flat, or V-Coated Wedged | 185 nm - 2.1 μm | Uncoated (Flat or Wedged) | - | Raw Data | - |

| -UV Coating, 245 - 400 nm (Flat or Wedged) | Ravg < 0.5% at 0° AOI | - | Raw Data | ||

| -C3 Coating, 261 - 266 nm (V-Coated) | Ravg < 0.5% at 0° AOI | - | Raw Data | ||

| -C6 Coating, 350 - 450 nm (V-Coated) | Ravg < 0.5% at 0° AOI | - | Raw Data | ||

| -A Coating, 350 - 700 nm (Flat or Wedged) | Ravg < 0.5% at 0° AOI | - | Raw Data | ||

| -B Coating, 650 - 1050 nm (Flat or Wedged) | Ravg < 0.5% at 0° AOI | - | Raw Data | ||

| -C Coating, 1050 - 1700 nm (Flat or Wedged) | Ravg < 0.5% at 0° AOI | - | Raw Data | ||

| Sapphire: Flat or Wedged | 200 nm - 5.0 μm | Uncoated | - | Raw Data | - |

| -D Coating, 1.65 - 3.0 µm | Ravg < 1.0% at 0° AOI | Raw Data | Raw Data | ||

| -E1 Coating, 2.0 - 5.0 µm | Ravg < 1.50%, Rabs < 3.0% (per Surface, 2.0 - 5.0 µm); Ravg < 1.75% (per Surface, 2.0 - 4.0 µm) at 0° AOI | Raw Data | Raw Data | ||

| Magnesium Fluoride (MgF2): Flat or Wedged | 200 nm - 6.0 μm | Uncoated | - | Raw Data | - |

| Barium Fluoride (BaF2): Flat or Wedged | 200 nm - 11 µm | Uncoated (Wedged Only) | - | Raw Data | - |

| -E1 Coating, 2 - 5 µm | Ravg < 1.25%; Rabs < 2.5% at 0° AOI | Raw Data | Raw Data | ||

| UV Fused Silica, for 45° AOI: Flat or Wedged | 250 nm - 1.6 µm | Coating for 250 nm - 450 nm | Ravg < 1.0% at 45° AOI | Raw Data | |

| Coating for 350 nm - 1100 nm | Ravg < 2.0% at 45° AOI | Raw Data | |||

| Coating for 400 nm - 700 nm | Ravg < 1.0% at 45° AOI | Raw Data | |||

| Coating for 600 nm - 1700 nm | Ravg < 1.5% at 45° AOI | Raw Data | |||

| Coating for 700 nm - 1100 nm | Ravg < 1.0% at 45° AOI | Raw Data | |||

| Coating for 1200 nm - 1600 nm | Ravg < 1.0% at 45° AOI | Raw Data | |||

| Potassium Bromide (KBr): Flat | 250 nm - 26 µm | Uncoated | - | - | |

| Infrasil®: Flat | 300 nm - 3 µm | Uncoated | - | Raw Data | - |

| N-BK7: Flat, Wedged, V-Coated Flat, or V-Coated Wedged | 350 nm - 2.0 μm | Uncoated (Flat or Wedged) | - | Raw Data | - |

| -A Coating, 350 - 700 nm (Flat or Wedged) | Ravg < 0.5% at 0° AOI | - | Raw Data | ||

| -C7 Coating, 400 - 700 nm (V-Coated) | Ravg < 0.5% at 0° AOI | - | Raw Data | ||

| -C10 Coating, 523 - 532 nm (V-Coated) | Ravg < 0.5% at 0° AOI | - | Raw Data | ||

| -C11 Coating, 610 - 860 nm (V-Coated) | Ravg < 0.5% at 0° AOI | - | Raw Data | ||

| -B Coating, 650 - 1050 nm (Flat or Wedged) | Ravg < 0.5% at 0° AOI | - | Raw Data | ||

| -C13 Coating, 700 - 1100 nm (V-Coated) | Ravg < 0.5% at 0° AOI | - | Raw Data | ||

| C14 Coating, 1047 - 1064 nm (V-Coated) | Ravg < 0.5% at 0° AOI | - | Raw Data | ||

| -C15 Coating, 523 - 532 nm & 1047 - 1064 nm (V-Coated) | Ravg < 0.5% at 0° AOI | - | Raw Data | ||

| -C Coating, 1050 - 1700 nm (Flat or Wedged) | Ravg < 0.5% at 0° AOI | - | Raw Data | ||

| Zinc Selenide (ZnSe): Flat or Wedged | 600 nm - 16 µm | Uncoated | - | Raw Data | - |

| -D Coating, 1.65 - 3.0 µm | Ravg < 1.0%; Rabs < 2.0% at 0° AOI | Raw Data | Raw Data | ||

| -E4 Coating, 2 - 13 µm (Only Flat) | Ravg < 3.5%; Rabs < 6% at 0° AOI | Raw Data | Raw Data | ||

| -E2 Coating, 4.5 - 7.5 µm (Only Flat) | Ravg < 1.0%; Rabs < 2.0% at 0° AOI | Raw Data | Raw Data | ||

| -E3 Coating, 7 - 12 µm (Only Wedged) | Ravg < 1.0%; Rabs < 2.0% at 0° AOI | Raw Data | Raw Data | ||

| -G Coating, 7 - 12 µm (Only Flat) | Ravg < 1% at 0° AOI | Raw Data | Raw Data | ||

| Silicon (Si): Flat or Wedged | 1.2 - 8.0 μm | Uncoated | - | Raw Data | - |

| -E1 Coating, 2 - 5 µm (Only Wedged) | Ravg < 1.25%; Rabs < 2.5% at 0° AOI | Raw Data | Raw Data | ||

| -E Coating, 3 - 5 µm (Only Flat) | Ravg < 2% at 0° AOI | Raw Data | Raw Data | ||

| Germanium (Ge): Flat or Wedged | 1.9 - 16 μm | Uncoated, 2.0 - 16 μm | - | Raw Data | - |

| -C9 Coating, 1.9 - 6 µm (Only Flat) | Ravg < 2% at 0° AOI | Raw Data | Raw Data | ||

| -E3 Coating, 7 - 12 µm | Ravg < 1.0%; Rabs < 2.0% at 0° AOI | Raw Data | Raw Data | ||

| Item # | UDP05 | UPD053 |

|---|---|---|

| Diameter | 1/2" (12.7 mm) | |

| Diameter Tolerance | +0.0 / -0.1 mm | +0.0 / -0.2 mm |

| Thickness | 1.0 mm | 3.0 mm |

| Thickness Tolerance | ±0.1 mm | ±0.3 mm |

| Clear Aperture | > 90% of Diameter | ≥80% of Diameter |

| Parallelism | < 5 arcmin | < 3 arcmin |

| Transmitted Wavefront Errora | < λ/10 Over Clear Aperture | |

| Surface Quality | 10-5 Scratch-Dig | |

| Wavelength Range | 300 nm - 3 µm (Uncoated) | |

| Substrate | Infrasil® | |

| Transmission Data | Raw Data | Raw Data |

| Item # | UDP10 | UDP105 | |

|---|---|---|---|

| Diameter | 1" (25.4 mm) | ||

| Diameter Tolerance | +0.0 / -0.1 mm | +0.0 / -0.2 mm | |

| Thickness | 1.0 mm | 5.0 mm | |

| Thickness Tolerance | ±0.1 mm | ±0.3 mm | |

| Clear Aperture | > 80% of Diameter | ≥ 85% of Diameter | |

| Parallelism | < 5 arcmin | < 3 arcmin | |

| Transmitted Wavefront Errora | < λ/10 Over Clear Aperture | ||

| Surface Quality | 10-5 Scratch-Dig | ||

| Wavelength Range | 300 nm - 3 µm (Uncoated) | ||

| Substrate | Infrasil® | ||

| Transmission Data | Raw Data | Raw Data | |

| Item # | UDP20 | |

|---|---|---|

| Diameter | 2" (50.8 mm) | |

| Diameter Tolerance | +0.0 / -0.2 mm | |

| Thickness | 1.0 mm | |

| Thickness Tolerance | ±0.1 mm | |

| Clear Aperture | ≥ 85% of Diameter | |

| Parallelism | < 3 arcmin | |

| Transmitted Wavefront Errora | < λ/10 Over Clear Aperture | |

| Surface Quality | 10-5 Scratch-Dig | |

| Wavelength Range | 300 nm - 3 µm (Uncoated) | |

| Substrate | Infrasil® | |

| Transmission Data | Raw Data | |

Products Home

Products Home

ズーム

ズーム

Infrasil®ウィンドウ(0.3~3 µm)

Infrasil®ウィンドウ(0.3~3 µm)