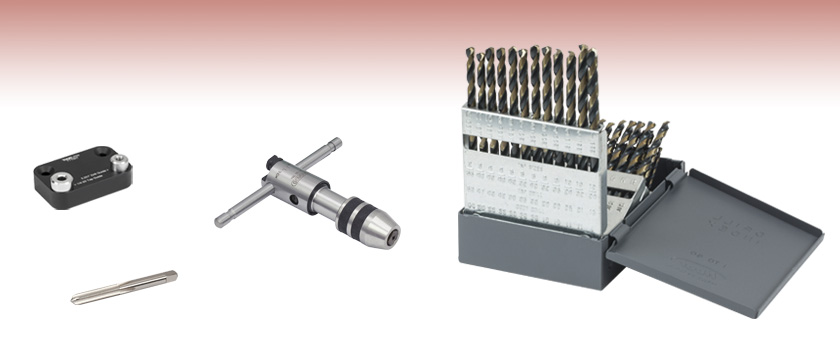

タップ&ドリルキット

- Individual Imperial & Metric Plug Taps

- 60-Piece Drill Bit Kit

- Tap Guides Help Ensure Tapped Holes are

Perpendicular to Flat Surfaces

TTT001

Tap Guide for Optical Tables and Breadboards

TAP1480

1/4"-80 Tap

TW25

Tap Wrench

DK3

60-Piece Drill Bit Kit

Please Wait

Click to Enlarge

当社のSM1ネジ規格のタップ加工用タップTAPSM1(インチ規格)

Click to Enlarge

当社のSM05ネジ規格のタップ加工用タップTAPSM05(インチ規格)

特長

- 当社のSM05およびSM1ネジ規格を含めた幅広いタップ切り用

- スチール製ケースに60本のドリルビットが入ったドリルキット

- カスタム用途に必要な汎用タップレンチ

- 破損したタップ穴を修復するためのテーブルおよびブレッドボード用タップガイド

こちらのページでご紹介している製品を使用して、ブレッドボードならびに光学テーブル上のご希望の位置にタップ穴を追加したり、破損したタップ穴を修復したりすることができます。

| SM05 Threading: Ø1/2" Lens Tubes, 16 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 0.535"-40.0 UNS-2A | Internal Thread, 0.535"-40.0 UNS-2B | ||

| Max Major Diameter | 0.5340" | Min Major Diameter | 0.5350" |

| Min Major Diameter | 0.5289" | Min Pitch Diameter | 0.5188" |

| Max Pitch Diameter | 0.5178" | Max Pitch Diameter | 0.5230" |

| Min Pitch Diameter | 0.5146" | Min Minor Diameter (and 83.3% of Thread) | 0.508" |

| Max Minor Diameter | 0.5069" | Max Minor Diameter (and 64.9% of Thread) | 0.514" |

| RMS Threading: Objective, Scan, and Tube Lenses | |||

|---|---|---|---|

| External Thread, 0.800"-36.0 UNS-2A | Internal Thread, 0.800"-36.0 UNS-2B | ||

| Max Major Diameter | 0.7989" | Min Major Diameter | 0.8000" |

| Min Major Diameter | 0.7934" | Min Pitch Diameter | 0.7820" |

| Max Pitch Diameter | 0.7809" | Max Pitch Diameter | 0.7866" |

| Min Pitch Diameter | 0.7774" | Min Minor Diameter (and 83.3% of Thread) | 0.770" |

| Max Minor Diameter | 0.7688" | Max Minor Diameter (and 64.9% of Thread) | 0.777" |

| C-Mount Threading: Machine Vision Lenses, CCD/CMOS Cameras | |||

|---|---|---|---|

| External Thread, 1.000"-32.0 UN-2A | Internal Thread, 1.000"-32.0 UN-2B | ||

| Max Major Diameter | 0.9989" | Min Major Diameter | 1.0000" |

| Min Major Diameter | 0.9929" | Min Pitch Diameter | 0.9797" |

| Max Pitch Diameter | 0.9786" | Max Pitch Diameter | 0.9846" |

| Min Pitch Diameter | 0.9748" | Min Minor Diameter (and 83.3% of Thread) | 0.966" |

| Max Minor Diameter | 0.9651" | Max Minor Diameter (and 64.9% of Thread) | 0.974" |

| SM1 Threading: Ø1" Lens Tubes, 30 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 1.035"-40.0 UNS-2A | Internal Thread, 1.035"-40.0 UNS-2B | ||

| Max Major Diameter | 1.0339" | Min Major Diameter | 1.0350" |

| Min Major Diameter | 1.0288" | Min Pitch Diameter | 1.0188" |

| Max Pitch Diameter | 1.0177" | Max Pitch Diameter | 1.0234" |

| Min Pitch Diameter | 1.0142" | Min Minor Diameter (and 83.3% of Thread) | 1.008" |

| Max Minor Diameter | 1.0068" | Max Minor Diameter (and 64.9% of Thread) | 1.014" |

| SM30 Threading: Ø30 mm Lens Tubes | |||

|---|---|---|---|

| External Thread, M30.5 x 0.5 – 6H/6g | Internal Thread, M30.5 x 0.5 – 6H/6g | ||

| Max Major Diameter | 30.480 mm | Min Major Diameter | 30.500 mm |

| Min Major Diameter | 30.371 mm | Min Pitch Diameter | 30.175 mm |

| Max Pitch Diameter | 30.155 mm | Max Pitch Diameter | 30.302 mm |

| Min Pitch Diameter | 30.059 mm | Min Minor Diameter (and 83.3% of Thread) | 29.959 mm |

| Max Minor Diameter | 29.938 mm | Max Minor Diameter (and 64.9% of Thread) | 30.094 mm |

| SM1.5 Threading: Ø1.5" Lens Tubes | |||

|---|---|---|---|

| External Thread, 1.535"-40 UNS-2A | Internal Thread, 1.535"-40 UNS-2B | ||

| Max Major Diameter | 1.5339" | Min Major Diameter | 1.535" |

| Min Major Diameter | 1.5288" | Min Pitch Diameter | 1.5188" |

| Max Pitch Diameter | 1.5177" | Max Pitch Diameter | 1.5236" |

| Min Pitch Diameter | 1.5140" | Min Minor Diameter (and 83.3% of Thread) | 1.508" |

| Max Minor Diameter | 1.5068" | Max Minor Diameter (and 64.9% of Thread) | 1.514" |

| SM2 Threading: Ø2" Lens Tubes, 60 mm Cage Systems | |||

|---|---|---|---|

| External Thread, 2.035"-40.0 UNS-2A | Internal Thread, 2.035"-40.0 UNS-2B | ||

| Max Major Diameter | 2.0338" | Min Major Diameter | 2.0350" |

| Min Major Diameter | 2.0287" | Min Pitch Diameter | 2.0188" |

| Max Pitch Diameter | 2.0176" | Max Pitch Diameter | 2.0239" |

| Min Pitch Diameter | 2.0137" | Min Minor Diameter (and 83.3% of Thread) | 2.008" |

| Max Minor Diameter | 2.0067" | Max Minor Diameter (and 64.9% of Thread) | 2.014" |

| SM3 Threading: Ø3" Lens Tubes | |||

|---|---|---|---|

| External Thread, 3.035"-40.0 UNS-2A | Internal Thread, 3.035"-40.0 UNS-2B | ||

| Max Major Diameter | 3.0337" | Min Major Diameter | 3.0350" |

| Min Major Diameter | 3.0286" | Min Pitch Diameter | 3.0188" |

| Max Pitch Diameter | 3.0175" | Max Pitch Diameter | 3.0242" |

| Min Pitch Diameter | 3.0133" | Min Minor Diameter (and 83.3% of Thread) | 3.008" |

| Max Minor Diameter | 3.0066" | Max Minor Diameter (and 64.9% of Thread) | 3.014" |

| SM4 Threading: Ø4" Lens Tubes | |||

|---|---|---|---|

| External Thread, 4.035"-40 UNS-2A | Internal Thread, 4.035"-40.0 UNS-2B | ||

| Max Major Diameter | 4.0337" | Min Major Diameter | 4.0350" |

| Min Major Diameter | 4.0286" | Min Pitch Diameter | 4.0188" |

| Max Pitch Diameter | 4.0175" | Max Pitch Diameter | 4.0245" |

| Min Pitch Diameter | 4.0131" | Min Minor Diameter (and 83.3% of Thread) | 4.008" |

| Max Minor Diameter | 4.0066" | Max Minor Diameter (and 64.9% of Thread) | 4.014" |

| Posted Comments: | |

user

(posted 2024-05-13 21:30:09.42) What is the distance from the bottom of the sm05 tap to the first full thread? cdolbashian

(posted 2024-05-24 09:55:56.0) As the taper on the threads are approximately 5-6 threads deep and the thread pitch is ~.635mm. As such the first full thread starts at around 3-4mm. I have contacted you directly to discuss your application and your need for a perhaps-more-specific value. Kyle Douglass

(posted 2024-03-28 08:32:33.53) Hello!

Would you also happen to sell dies for creating SM1 external threads? I've only been able to find taps on your website.

Many thanks. jdelia

(posted 2024-03-28 01:08:31.0) Thank you for contacting Thorlabs. We unfortunately do not currently offer dies as part of our catalog. I have reached out to you directly to discuss alternative vendors. chua ss

(posted 2023-10-26 15:51:12.683) Dear Sir/Madam,

Kindly quote us the current price and the shipping charges as below ;

1. MACHINE TAP (THOR) PO 0.535" X 40

Q’ty : 5pcs

Your prompt reply on the above mentioned is highly appreciated.

Thanks and Regards.

S.S. Chua (Ms)

Purchase Coordinator

Creative Precision Engineering Sdn. Bhd. [CO. NO :199101017821 (228132-T)]

32, Lorong IKS Juru 3, IKS Juru,

14100 Simpang Ampat,

Penang, Malaysia.

Tel : 604-5071330, Ext : 120

H/P : +012-5681921

Email : pur02@creative-pe.com jdelia

(posted 2023-10-26 02:45:19.0) Thank you for contacting Thorlabs. You may request a quote for the TAPSM05 by reaching out to your local sales team at sales@thorlabs.com or 973-300-3000, or by adding the item to your shopping cart directly on the website. Maxwell Lightstone

(posted 2023-02-01 17:02:56.033) Can you sell a 25.75 mm drill bit to go with the SM1 tap? There isn't a good way to drill those holes right now, and we don't always want to use a lathe or a mill.

Best regards,

Maxwell Lightstone, MASc

Mechanical Engineer jdelia

(posted 2023-02-03 03:04:51.0) Thank you for your feedback. We unfortunately do not offer a drill bit for SM1 taps as we typically suggest milling out a pilot bore. I have contacted you directly to discuss your application and the possibility of offering this in the future. Ahn Chang-Joon

(posted 2023-01-14 23:41:30.687) I found the tool Tapsm1 for SM1 Internal Thread here.

However, no tools can be found for the SM1 External Thread.

Can I purchase a tool for this?

If possible, please reply to mertul@kit-fa.com jdelia

(posted 2023-01-17 04:30:58.0) Thank you for contacting Thorlabs. I have reached out to you directly to discuss your application as well as methods that will allow you to cut external SM1 threads. Enrico Renna

(posted 2022-08-03 14:31:43.523) Hello, would it be possible to buy a tap for SM18 thread ? We still have some issue to produce something that would function with the SM18RR. I couldn't find it on the webpage. Thank you very much! jdelia

(posted 2022-08-03 03:02:30.0) Thank you for contacting Thorlabs. We will reach out to you directly regarding the possibility of quoting this out to you as a custom part. Evgeny Rozemblit

(posted 2021-12-20 06:15:41.993) Hello,

Need your help, do you know where I can find the GO-NOT GO gauge for 0.800"x36 thread? jgreschler

(posted 2021-12-23 10:46:46.0) Thank you for reaching out to Thorlabs. I have reached out to you directly to discuss this further. user

(posted 2021-08-11 11:36:02.887) It would be helpful if both bottoming and plug taps were offered for the SM05 and SM1 threads. The plug tap with the tapered threading doesn't work well on shallow depth holes. cdolbashian

(posted 2021-08-27 11:10:48.0) Thank you for your suggestion! As we are hungry for feedback, we will look into the potential availability of this product as a stock option in the future. user

(posted 2021-04-12 03:34:23.157) Hi, does Thorlabs sell M38 x 0.5 taps to accommodate the thread of the TTL-200 tube lens?

I need to use that lens directly in a custom mount that is too small for the SM2 thread of the TTL200-A or the adapter. YLohia

(posted 2021-04-12 04:42:49.0) Hello, custom taps can be requested by clicking on the "Request Quote" button above or by contacting your local Thorlabs Tech Support team (in your case, techsupport.se@thorlabs.com). We will discuss the possibility of offering this directly. Frank Seifert

(posted 2019-11-05 12:56:04.46) Hi, it is great that Thorlabs offers a lot of the special taps (metric & imperial) to allow the customer to do their own adapters. However I'm missing the M15.5 x 0.5 tap for the

SM15RR. Is it possible to purchase a M15.5 x 0.5 tap? Thanks! llamb

(posted 2019-11-06 09:49:47.0) Thank you for your feedback! Custom taps can be requested by clicking the red "Request Quote" button above or emailing techsupport@thorlabs.com. I have reached out to you directly in this case to discuss this possibility. Chris Betters

(posted 2019-04-08 04:44:40.833) Can you provide a tap for SMA threads (1/4-32)?

Thanks Chris YLohia

(posted 2019-04-09 03:13:43.0) Hello Chris, thank you for contacting Thorlabs. Custom taps can be requested by clicking the red "Request Quote" button above or emailing techsupport@thorlabs.com. We will reach out to discuss your requirements. ghovorka

(posted 2019-01-16 09:57:30.87) It would be very useful to have a tap for M10.5x0.5 threads. It is a great size for mounting 10mm OD optics with the SM10RR retaining ring, but can't be used as easily for custom mounts without a tap available. llamb

(posted 2019-01-17 12:02:50.0) Thank you for your feedback. I have added this idea into our internal product forum for further discussion. We can currently offer the M10.5 x 0.5 plug tap as a special item. I have reached out to you by email directly to discuss this special quote. kitchinsf

(posted 2018-10-24 16:12:02.7) It would be helpful to offer a tap guide for ensuring perpendicular taps to the work surface. Since the SM05, SM1, and SM2 are not very common outside of Thor, a tap guide that includes these (at least the SM05 and SM1, SM2 is a bit too large) it would be very helpful. The table tap guide is very useful but is limited in its functionality. llamb

(posted 2018-11-05 10:48:40.0) Thank you for your feedback. Tap guides like the TTT001(/M) typically need a flat reference plane like an optical table to fix to first. Most optomechanical parts with SM- threads are rounded or cylindrical, making it difficult to create a standardized tapping guide that fits to all components. We do not recommend hand-tapping these larger threads, but instead recommend using a type of drill press with a clutch for reversing the tap out of the threads. wenzel.jakob

(posted 2017-12-02 22:26:07.137) I'm also interested in a tap for SM2 threads. Could you please provide me with a quote? Thank you. tfrisch

(posted 2017-12-05 01:54:35.0) Hello, thank you for contacting Thorlabs. We will reach out to you with a quote for an SM2 tap. pierrick.cheiney

(posted 2017-06-21 13:57:27.263) Hello,

I cannot find a tap for the SM2 threads. Would it be possible to get one?

Thanks, tfrisch

(posted 2017-06-27 11:19:36.0) Hello, thank you for contacting Thorlabs. We will reach out to you with a quote. user

(posted 2017-03-15 08:46:56.48) What tapping depth can each tap achieve?! This is key info that needs to be added to this webpage. Also of interest are: overall length, shank diameter. tcampbell

(posted 2017-03-23 01:55:10.0) Response from Tim at Thorlabs: thank you for your feedback. We have added the thread depth and overall length of each tap to the webpage. ludoangot

(posted 2016-09-26 11:22:33.873) Hello, it would be very useful and convenient if you could offer precision quality individual drill in the sizes required for the taps you sell. jlow

(posted 2016-09-29 10:55:03.0) Response from Jeremy at Thorlabs: Thank you for your feedback, we will look into offering these. johannes.hohlbein

(posted 2016-06-27 09:37:37.37) I would also be interested in a tap to match the SM2 lens tube system. acaballero

(posted 2016-05-10 10:03:46.95) I could really use a tap to match the SM2 lens tube system. besembeson

(posted 2016-05-10 04:59:37.0) Response from Bweh at Thorlabs USA: We can provide this to you. I will follow-up via email. cbrideau

(posted 2016-01-04 19:09:52.09) An 8/32 imperial tap would be very useful to complement the M4 metric tap. besembeson

(posted 2016-01-05 08:26:53.0) Response from Bweh at Thorlabs USA: We typically stock and provide mostly specialty taps that aren’t easily found as a convenience to those looking to integrate our components in their systems. As #8-32 is a very common thread, its tap can be easily found at local convenient stores or many other places online so we don't stock this. ghall

(posted 2015-11-24 11:50:45.943) What style of taps are those? For through holes or bottoming?

What class are they in terms of the tolerance/allowance?

Specifically looking at the M11x0.5 tap. besembeson

(posted 2015-12-02 12:12:21.0) Response from Bweh at Thorlabs USA: This is a 4 flute, straight flute hand tap with a 6H class fit. cbrideau

(posted 2014-01-13 14:58:47.927) What would you recommend for drilling out a broken-off cap screw? The stainless steel of the screw is quite hard, so I'm not sure what would have a decent chance of actually boring through it... jlow

(posted 2014-01-14 02:59:05.0) Response from Jeremy at Thorlabs: You can use a sharp carbide drill bit for this. You can use a sharp punch and a hammer to create a pilot first. The screw is susceptible to hardening, so once you begin the drill process, you should not stop until you are through the screw. Also, there should be a steady stream of some sort of cutting fluid on the drill bit so it does not get too hot. Your university machine shop or a local machine shop should have this cutting fluid readily available. user

(posted 2013-11-07 15:40:06.927) Why not sell the die too? jlow

(posted 2013-11-11 10:54:51.0) Response from Jeremy at Thorlabs: We do not stock the dies but we can provide it. Since you did not leave your contact info, can you contact us at techsupport@thorlabs.com to request a quote for the die you are looking? Thanks. user

(posted 2013-07-15 16:12:23.917) Worst drill bit set ever!. Tried to drill through copper 1/4" copper and was not able to because the drills are just dull. I would not sell these at all. cdaly

(posted 2013-07-18 10:15:00.0) Response from Chris at Thorlabs: Thank you for your feedback. It may be a matter of drill speed and feed. Please contact as at techsupport@thorlabs.com to discuss the conditions further. nejbauer

(posted 2013-03-19 07:25:05.243) Hi,

Do you have taps for imperial thread 8-32, which is very popular in your products?

Best regards,

Michal Nejbauer tcohen

(posted 2013-03-21 15:51:00.0) Response from Tim at Thorlabs to Michal: Thank you for contacting us! We look to stock specialty taps that aren’t easily found as a convenience to those looking to integrate our components in their devices. #8-32 is a ubiquitous tap and you will most probably have luck finding it at your local hardware store. jlow

(posted 2012-07-31 15:26:00.0) A response from Jeremy at Thorlabs: We will get in contact with you directly regarding a quote for this. sfnagle

(posted 2012-07-31 13:52:09.0) I was wondering if you sell the die that goes with this tap size. I need to make external SM1 threads for a custom part in my set-up. Thanks. gregory.futia

(posted 2010-12-15 16:44:34.0) Where do you get a .508" through drill to use with the SM05 tap, 83373? |

Click to Enlarge

標準タップの図面

- カスタムのタップ切り用

- SM05、SM1など当社が使用するほとんどのネジに対応可能

- 材質:高速度鋼

これらのタップは、カスタム仕様のデバイスに当社のオプトメカニクス部品を組み込む際にお使いいただけます。インチ規格タップのラインナップには、SM05ならびにSM1規格など、当社で使用されているネジ規格の多くが含まれます。 ミリ規格のタップにつきましては上記をご覧ください。

タップ加工

タップ加工を施す際には、まず右表のパイロット穴径の欄を参照にパイロット穴を機械加工します。パイロット穴はドリルビットまたはエンドミルを使用して開けることができます。精密ピッチのネジ深さは浅いため、パイロット穴の公差を厳しくする必要があります。この場合、リーマのご使用もお勧めします。

次にタップを タップレンチ、ボール盤、または旋盤に固定し、ネジ加工を施します。 穴を開ける際は、潤滑油やタップ液をご使用ください。 タップ加工中に抵抗を感じる場合には、慎重にタップを逆回転させます。加工中にタップが折れてしまうと、取り除くことが困難になりますのでご注意ください。

こちらのタップを用いて穴を開ける際は、精密リングならびにプラグゲージで穴の直径をご確認ください。ネジ加工やタップ加工の詳細については市販されている機械ハンドブックをご参照ください。

| Item # | Thread Type | Thread Depth (T) | Overall Length (L) | Shank Size (S) | Pilot Bore | Example Uses | ||

|---|---|---|---|---|---|---|---|---|

| Diameter | Tolerancea | Imperial Drill Sizeb | ||||||

| TAP080 | 0-80 | 0.31" | 1.63" | 0.141" | 0.049" | +0.003"/-0.002" | - | Holes for Locking Setscrews |

| TAP256 | 2-56 | 0.44" | 1.75" | 0.141" | 0.070" | ±0.004" | #50 (0.0700") | Mounting Holes on Miniature Translation Stages |

| TAP440 | 4-40 | 0.56" | 1.88" | 0.141" | 0.089" | ±0.005" | #43 (0.0890") | Holes for Cage Rod Locking Setscrews |

| TAP680 | 6-80 | 0.69" | 2.00" | 0.141" | 0.126" | ±0.002" | 1/8" (0.1250") | Holes for 6-80 Adjustment Screws |

| TAP832 | 8-32 | 0.75" | 2.13" | 0.168" | 0.135" | +0.004"/-0.005" | #29 (0.1360") | Mounting Holes for 8-32 Screws |

| TAP316100 | 3/16"-100 | 0.88" | 2.38" | 0.194" | 0.177" | +0.002"/-0.001" | #16 (0.1770") | Holes for 3/16"-100 Adjustment Screws |

| TAP1420 | 1/4"-20 | 1.00" | 2.50" | 0.255" | 0.202" | +0.005"/-0.006" | #7 (0.2010") | Mounting Holes for 1/4"-20 Screws |

| TAP1480 | 1/4"-80 | 1.00" | 2.50" | 0.255" | 0.238" | ±0.002" | B (0.2380") | Holes for 1/4"-80 Adjustment Screws |

| TAP14100 | 1/4"-100 | 1.00" | 2.50" | 0.255" | 0.240" | +0.002"/-0.001" | - | Holes for 1/4"-100 Adjustment Screws |

| TAP51632 | 5/16"-32 | 1.13" | 2.72" | 0.318" | 0.282" | +0.004"/-0.003" | 9/32" (0.2812") | Mounting Holes for 3/16"-100 Locking Bushings with 5/16"-32 External Threads |

| TAP3824 | 3/8"-24 | 1.25" | 2.94" | 0.381" | 0.335" | ±0.005" | Q (0.3340") | Mounting Hole for HAFC Fiber Bulkhead Adapter, 3/8" Standard Tapped Holes |

| TAP3840 | 3/8"-40 | 1.25" | 2.94" | 0.381" | 0.348" | ±0.003" | S (0.3480") | Mounting Holes for 1/4"-80 Locking Bushings with 3/8"-40 External Threads |

| TAP38100 | 3/8"-100 | 1.25" | 2.94" | 0.381" | 0.365" | +0.002"/-0.001" | - | Holes for 3/8"-100 Fine Adjustment Screws |

| TAPSM05 | 0.535"-40 (SM05 Standard) | 1.66" | 3.59" | 0.429" | 0.511" | ±0.003" | - | Internal Threads on Ø1/2" Lens Tubes |

| TAPRMS | 0.800"-36 (RMS Standard) | 2.00" | 4.47" | 0.652" | 0.773" | +0.004"/-0.003" | - | Mounts for RMS-Threaded Objectives |

| TAPCM | 1.00"-32 (C-Mount Standard) | 2.50" | 5.13" | 0.800" | 0.970" | ±0.004" | - | Internal Threads on C-Mount Extension Tubes, Mounts for Machine Vision Camera Lenses |

| TAPSM1 | 1.035"-40 (SM1 Standard) | 1.50" | 4.00" | 0.896" | 1.011" | ±0.003" | - | Internal Threads on Ø1" Lens Tubes |

Click to Enlarge

標準タップの図面

- カスタムのタップ切り用

- 当社が使用しているほとんどのネジに対応

- 材質:高速度鋼

こちらのタップは、カスタム仕様のデバイスに当社のオプトメカニクス部品を組み込む際にお使いいただけます。ミリ規格タップのラインナップには、当社で使用されているネジ規格の多くが含まれます。インチ規格のタップ、ならびに当社のSM05ならびにSM1規格につきましては下記をご参照ください。

タップ加工

タップ加工を施す際には、まず右表のパイロット穴径の欄を参照にしながらパイロット穴を機械加工します。パイロット穴は、ドリルビットまたはエンドミルを使用して開けることができます。精密ピッチのネジ切り深さは浅いため、パイロット穴の公差を厳しくする必要があります。この場合、リーマのご使用もお勧めします。

次にタップをタップレンチ、ボール盤、または旋盤に固定し、ネジ加工を施します。穴を開ける際は、潤滑油やタップ液をご使用ください。タップ加工中に抵抗を感じる場合には、慎重にタップを逆回転させます。加工中にタップが折れてしまうと、取り除くことが困難になりますのでご注意ください。

こちらのタップを用いて穴を開ける際は、精密リングならびにプラグゲージで穴の直径をご確認ください。ネジ加工やタップ加工の詳細については市販の機械ハンドブックをご参照ください。

| Item # | Thread Type | Thread Depth (T) | Overall Length (L) | Shank Size (S) | Pilot Bore | Example Uses | |||

|---|---|---|---|---|---|---|---|---|---|

| Diameter | Tolerancea | Metric Drill Sizeb | Imperial Drill Sizeb | ||||||

| TAPM202 | M2 x 0.2 | 11.35 mm | 44.7 mm | 2.72 mm | 1.805 mm | +0.013 mm/-0.026 mm | 1.80 mm (0.0709") | - | Holes for M2 x 0.2 Adjustment Screws |

| TAPM2502 | M2.5 x 0.2 | 12.7 mm | 46.0 mm | 3.58 mm | 2.313 mm | ±0.030 mm | 2.3 mm (0.0905") | - | Holes for M2.5 x 0.2 Adjustment Screws |

| TAPM302 | M3 x 0.2 | 16.0 mm | 49.3 mm | 3.58 mm | 2.813 mm | ±0.030 mm | 2.8 mm (0.1102") | #34 (0.1110") | Holes for M3 x 0.2 Adjustment Screws |

| TAPM3025 | M3 x 0.25 | 16.0 mm | 49.3 mm | 3.58 mm | 2.766 mm | ±0.037 mm | 2.75 mm (0.1083") | 7/64" (0.1093") | Holes for M3 x 0.25 Adjustment Screws |

| TAPM4025 | M4 x 0.25 | 19.1 mm | 54.1 mm | 4.27 mm | 3.77 mm | ±0.037 mm | 3.75 mm (0.1476") | #26 (0.1470") | Holes for M4 x 0.25 Fine Adjustment Screws |

| TAPM407 | M4 x 0.7 (M4 Standard) | 19.1 mm | 54.0 mm | 4.27 mm | 3.332 mm | ±0.090 mm | 3.3 mm (0.1299") | #30 (0.1285") | Mounting Holes for M4 Screws |

| TAPM4505 | M4.5 x 0.5 | 22.4 mm | 60.5 mm | 4.93 mm | 4.029 mm | ±0.070 mm | 4.0 mm (0.1575") | #21 (0.1590") | Mounting Hole for M3 x 0.25 Adjuster Nutc |

| TAPM6025 | M6 x 0.25 | 25.4 mm | 63.5 mm | 6.48 mm | 5.575 mm | ±0.0165 mm | 5.6 mm (0.2205") | #2 (0.2210") | Holes for M6 x 0.25 Adjustment Screws |

| TAPM605 | M6 x 0.5 | 25.4 mm | 63.5 mm | 6.48 mm | 5.526 mm | ±0.068 mm | 5.5 mm (0.2165") | 7/23" (0.2187") | Mounting Bores for Aspheric Lens Housingsd |

| TAPM610 | M6 x 1.0 (M6 Standard) | 25.4 mm | 63.5 mm | 6.48 mm | 5.035 mm | ±0.118 mm | 5.1 mm (0.2008") | #8 (0.1990") | Mounting Holes for M6 Screws |

| TAPM7505 | M7.5 x 0.5 | 28.7 mm | 69.0 mm | 8.08 mm | 7.026 mm | +0.068 mm/-0.067 mm | - | - | Mounting Bores for Ø7 mm Optic Mounts |

| TAPM805 | M8 x 0.5 | 28.7 mm | 69.1 mm | 8.08 mm | 7.526 mm | ±0.068 mm | 7.5 mm (0.2953") | M (0.2950") | Mounting Bores for Aspheric Lens Housingsd |

| TAPM905 | M9 x 0.5 | 31.8 mm | 74.7 mm | 9.68 mm | 8.526 mm | ±0.068 mm | 8.5 mm (0.3346") | Q (0.3340") | Mounting Bores for Aspheric Lens Housingsd |

| TAPM1005 | M10 x 0.5 | 31.8 mm | 74.7 mm | 9.68 mm | 9.526 mm | ±0.068 mm | 9.5 mm (0.3740) | 3/8" (0.3750") | Mounting Bores for Aspheric Lens Housingsd |

| TAPM10505 | M10.5 x 0.5 | 31.8 mm | 74.7 mm | 9.70 mm | 10.026 mm | +0.068 mm/-0.067 mm | - | - | Mounting Bores for Ø10 mm Optic Mounts |

| TAPM1105 | M11 x 0.5 | 36.6 mm | 80.3 mm | 8.20 mm | 10.526 mm | ±0.068 mm | 10.5 mm (0.4133") | Z (0.4130") | Mounting Holes for Mounted Aspheric Lens Pair Housingsd |

| TAPM1205 | M12 x 0.5 | 42.1 mm | 85.7 mm | 9.32 mm | 11.526 mm | ±0.068 mm | 11.5 mm (0.4528") | 29/64" (0.4531") | Mounting Bores for Aspheric Lens Housingsd |

| TAPM1405 | M14 x 0.5 | 42.2 mm | 91.2 mm | 10.90 mm | 13.526 mm | ±0.068 mm | 13.5 mm (0.5315") | 17/23" (0.5312") | - |

| TAPM20505 | M20.5 x 0.5 | 50.8 mm | 113.5 mm | 16.56 mm | 20.026 mm | +0.068 mm/-0.067 mm | - | - | Mounting Bores for for Ø20 mm Lens Mounts |

| TAPM25075 | M25 x 0.75 (M25 Standard) | 63.5 mm | 130.3 mm | 20.32 mm | 24.284 mm | ±0.096 mm | - | - | Mounts for M25-Threaded Objectives |

- #1~#60の番号サイズのドリルビット60本

- 材質:高速度鋼

- 先端角135°

- スチール製ケースにはサイズの刻印

ドリルキットDK3は60本のレギュラ(レングス)ドリルビットがセットになっています。ドリルは高速度鋼製で、先端角は135°です。キットは、コンパクトなスチール製インデックス付きケースに収められ、ケースにはビットサイズ、タップドリルサイズ、クリアランスサイズが刻印されています。

Click to Enlarge

スライド構造のクロスバー

- スライド構造のクロスバー付き汎用タップレンチ

- M2~M6または#0~1/4インチのタップに対応

- シャンク(柄部)のサイズは、3.6 mm~6.5 mmまたは0.141インチ~0.255インチまで対応

機械加工作業でご利用いただける品質のタップレンチで、日常的なタッピング作業に適しています。頑丈なステンレススチール設計で、製品寿命が長く耐久性の高い製品となっています。スライド構造のクロスバーを使用いただくと、必要に応じてより大きなトルクを与えることができます。レンチの上部にあるノブを使用して、どちらの方向にもクロスバーを動かすことが可能です(右の写真参照)。このタップレンチは最小2 mm、最大6 mm(インチ規格:#0~1/4インチ)のタップに対応しています。

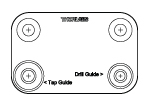

Click for Details

タップガイドTTT001(/M)の寸法(カッコ内の寸法がミリ規格品の寸法)

- 光学テーブルやブレッドボードのM6タップ穴を加工または修復

- ブッシュにより作業面に対して垂直なタップ穴を加工可能

- M6皿ネジが2本付属

タップガイドTTT001/Mは、ネジが折れたり縦傷がついたことにより破損した光学テーブルやブレッドボードの穴を再度ドリルで開け、タップ加工する際のガイドしてお使いいただけます。 M6ネジ穴の配列に合わせてガイドを固定できる皿ネジが2本付属します。 硬質で工具グレードのスチール製ブッシュのインサートは、折れたネジドリルで穴から取り除くための精密ガイドの役割にもなります。 そしてもう1つのブッシュは、タップ用のガイドであり、穴を修復し、確実に作業面に対して垂直にネジ切りします。

タップの破損は主に、タップ回転時に不必要な横方向への動きが生じ、同時にドリル軸に対して平行な力が加わっていないときに起こります。 このガイドは、このような事態を防ぐことができます。 折れたネジが詰まった穴を再度ドリルで開ける際には、先端が鋭利でカーバイドチップ付きのドリルビットをご使用になることをお勧めします。 タップガイドを取り付ける際には、皿ネジを締め付けすぎないようご注意ください。

Products Home

Products Home

ズーム

ズーム

ドリル/タップ類

ドリル/タップ類